What is a Two-Stage Rotary Vane Vacuum Pump?

What is a Two-Stage Rotary Vane Vacuum Pump?

A Two-Stage Rotary Vane Vacuum Pump is an oil-sealed vacuum pump used in many laboratory, scientific and production vacuum systems. These pumps have both a high and low-pressure vacuum stage, which improves the vacuum pump performance. The rotor chambers are lubricated with a specifically formulated oil which acts as a sealant and lubricant between the sliding vanes, pump rotor and stator. Most laboratory rotary vane pumps are direct drive coupled pumps and typically get to a base pressure of near 1 x 10-3 torr (1.3 mbar).

How does a Two-Stage Rotary Vane Pump Work?

The pumping action works on the principle of reducing the gas by gradually increasing the pump volume within the pumping cavity. The vanes rotate inside the stators and slide within the rotors. They are sealed by a specifically formulated, low vapor pressure oil, which acts as a sealant, lubricant, and coolant for the vacuum pump (You can find the right oil for your pump here). The two-stages are the high pressure and the low pressure. Gas enters the inlet or suction chamber (high pressure stage) and is transferred to the low-pressure stage where it is immediately compressed by the vane of the rotor and expelled to atmospheric pressure. The second stage improves base pressure or vacuum level of the pump.

What are the Advantages and Disadvantages of using Two-Stage Rotary Vane Vacuum Pumps?

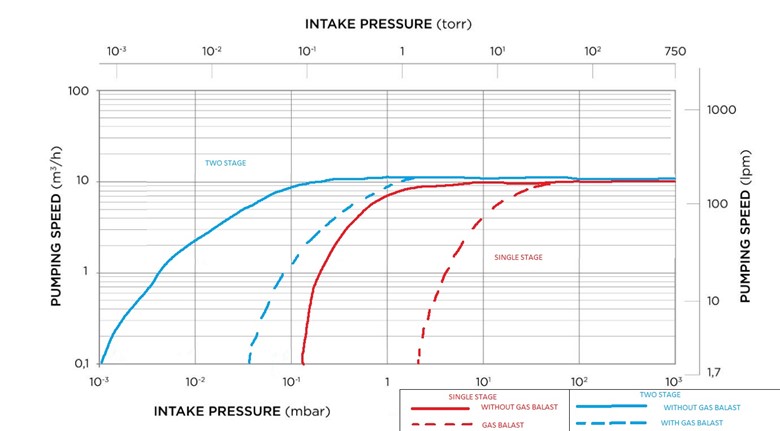

When compared to a single-stage oil-sealed rotary vane vacuum pump, two-stage vacuum pumps create lower vacuum levels, along with higher volumetric flow rates over a wider pressure range. The pumping speed is essentially the same for both pumps in the rough vacuum range, but as the absolute pressure passes 1 Torr, the two-stage vacuum pump continues to maintain its pumping speed, whereas the single-stage vacuum pump starts to decline.

Based on the graph provided, a single-stage pump would be adequate for vacuum levels down to about 1 Torr and would be lower cost (about 30% to 50% less. On the other hand, the performance of a single-stage vacuum pump begins to decrease after 1 Torr, so a two-stage pump becomes the obvious choice. The graph shows typical pumping speeds of single and two-stage vacuum pumps with and without the gas ballast valve open.

Why is a Gas Ballast Valve Necessary and When Should I use it?

Using a gas ballast is helpful when pumping contaminants like water vapor, acetone, alcohols, and other condensable vapors. A gas ballast valve admits air into the vacuum pump to assist in discharging condensable gases before they condense inside the pump. This process protects the vacuum pump, but it will decrease the performance of the pump as seen in the graph provided above.

What is the Right Vacuum Pump Oil for Two-Stage Rotary Vane Vacuum Pumps?

If your vacuum pump is always getting contaminated, requiring you to change the oil often, 19 Grade is the best vacuum pump oil option for you. This vacuum oil is the lower-priced option but still has a premium performance. This is a higher viscosity, designed for direct-drive rotary vane vacuum pumps, and ideal for most general-purpose applications. The low vapor pressure reduces system back streaming and thermal stability provides resistance to oxidation and sludge formation.

20 Grade is an upgraded oil from the 19 Grade. It is a severely hydro-treated paraffinic oil that is double distilled through a molecular distillation process to remove light end fractions. 20 Grade is highly saturated and contains less than 0.01% sulfur similar to technical white oils. Its high molecular weight and viscosity index provides longer service life and reduced build-up of varnish and carbonized oil on the internal pump components.

If you want your oil to last a long time so you don't have to spend time changing it, Elite Z is the option for you. This oil is double distilled to exhibit the highest performance for mechanical pumps. EZ Grade is a full synthetic hydrocarbon vacuum fluid that is very resistant to thermal and chemical attacks and provides longer oil life and superior protection to the vacuum pump.